The solution has been implemented successfully and will enhance El Nino’s existing capabilities. The new warehouse at El Nino is now fully operational.

“Our goal was to find a solution that would improve the efficiency of El Nino’s existing capabilities. After a thorough analysis, we proposed the best option was to move the entire storage system from three halls to one robotic and automated hall,” says Jindřich Kadeřávek, Managing Director at Element Logic Czech Republic.

The completion of this project represents a significant milestone in El Nino’s efforts to streamline its operations and improve overall efficiency.

Increasing the number of picked orders

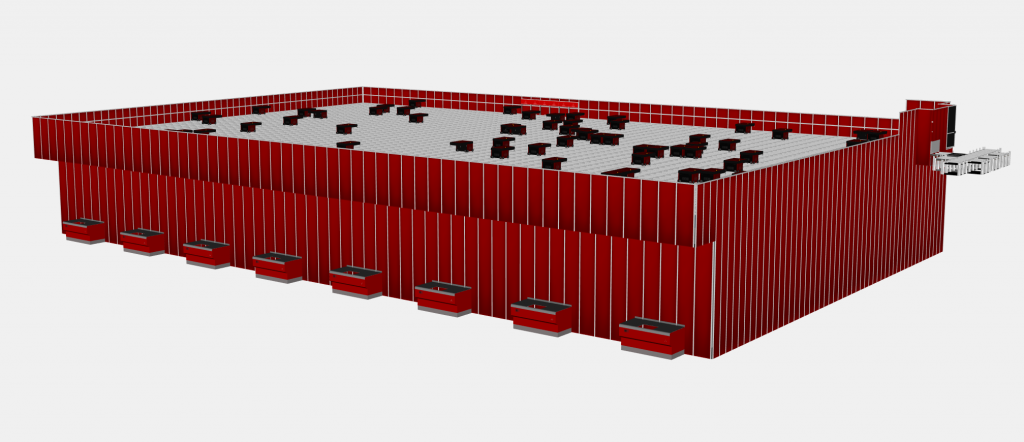

The AutoStore solution at El Nino’s new warehouse will accommodate 40,000 bins and is serviced by 58 robots in the first phase. It also includes 9 carousel ports for storage and picking.

“The installation of AutoStore has resulted in a smoother process for dispatching individual orders and easier planning of human resources during anticipated seasonal increases. In times of low unemployment, El Nino can efficiently cover these peaks with minimal cost.”, says Zdeněk Augusta, COO of El Nino.

By deploying the automated storage system, El Nino expects to increase the number of picked orders. Additionally, the future capacity and performance expansion will be simple, modular, and without operational limitations with the AutoStore system.

El Nino specializes in selling hundreds of perfumes and cosmetic brands that are delivered throughout Europe. The company dispatches tens of thousands of orders every day, which are delivered to their customers as quickly as possible. Despite the increase in orders, Zdeněk Augusta assures that El Nino will continue to provide their customers with the very high standard they are accustomed to.

Facts and figures El Nino

- Number of bins: 40,000

- Number of robots: 58 robots

- Number of ports: 9 carousel ports

- Picking efficiency increased by up to 50%

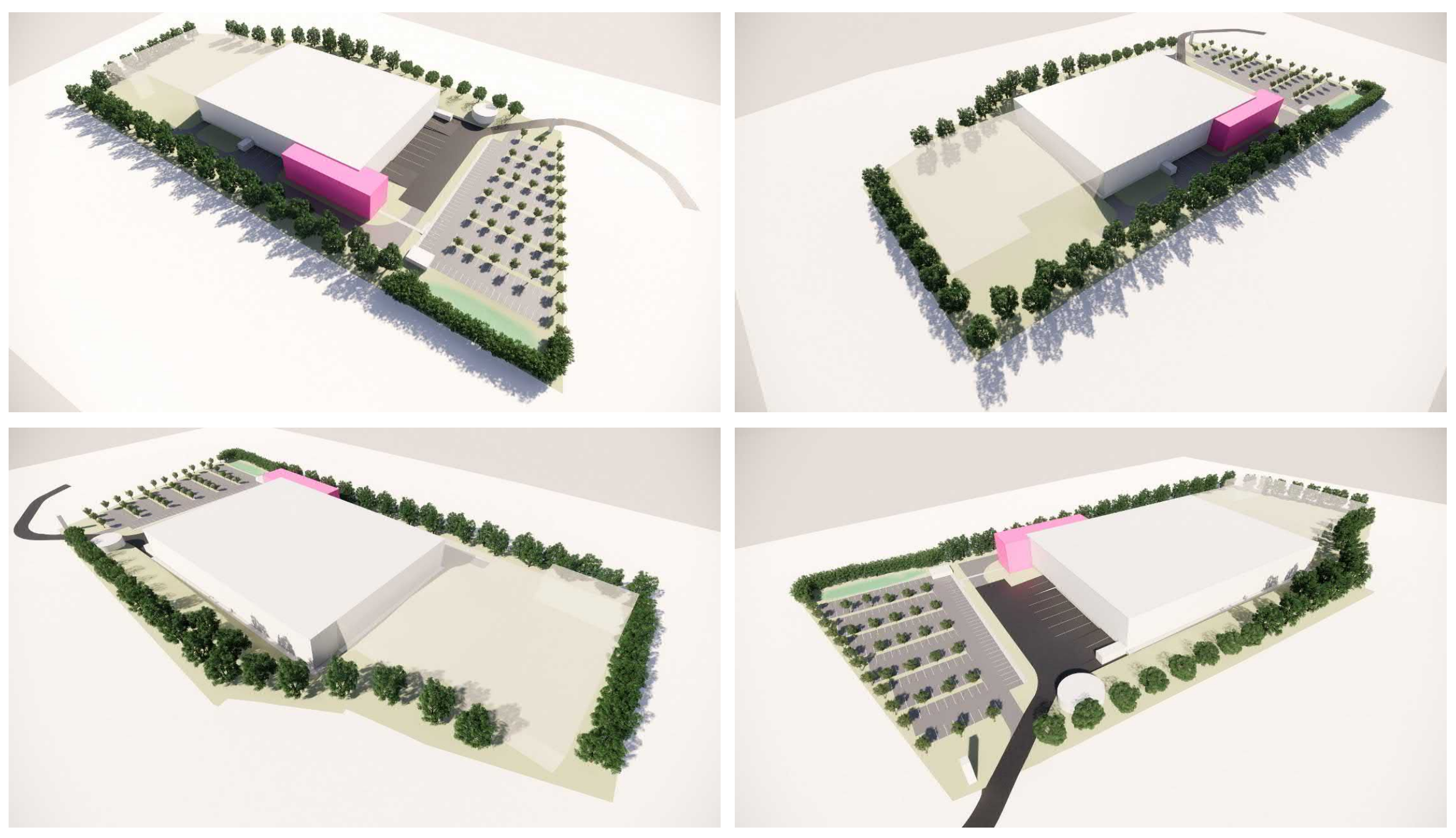

- Warehouse size: Over 8,000 m2

- Operational in: Second half of 2022