Berggaard Amundsen’s futuristic warehouse and headquarter outside of Oslo is quite unique: Because the electronics wholesaler wanted their new 14,000 m2 building to act as a visual representation of the products they sell, they had 1,050 solar panels installed on the roof – as well as solar panels covering 50 m2 of the façade.

Even in Norway, with little sunlight and snow during the winter season, the facility generates 230.000 kilowatt hours of pure solar energy a year. The solar panels make Berggaard Amundsen (BA) self-sufficient from April to September and also provide power to 40 electrical car chargers that are available to use for the local neighborhood. As a result, BA received an «Eco-lighthouse» certification for setting up an environmentally friendly warehouse facility.

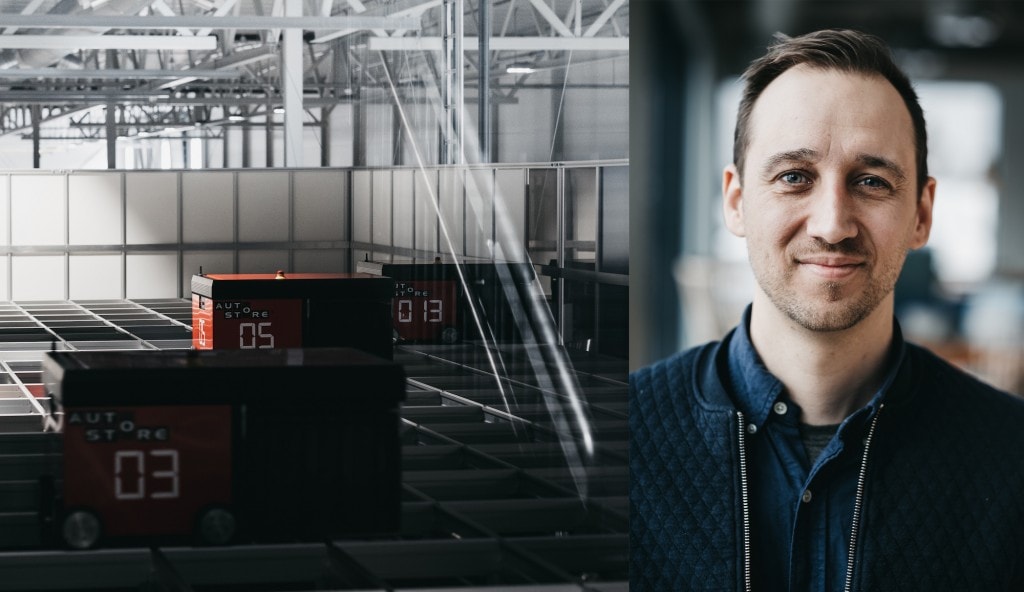

«The AutoStore robots’ energy consumption is extremely low, and they regenerate power every time they lower a bin or reduce speed – just like an electrical car. This means they are a perfect fit for sustainable warehouses. Berggaard Amundsen’s warehouse is better for the environment and also cost-efficient. It’s a win-win» says Niklas Poulsen from System Sales at Element Logic.

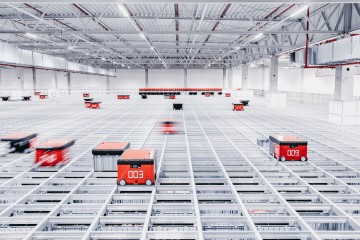

The BA warehouse’s grid holds 17,000 bins, with 17 robots doing the work. Considering that ten robots use the same amount of energy as one vacuum cleaner, and 70 percent of BA’s picking is done through AutoStore, it’s evident that the overall energy consumption in the new warehouse is very low compared to other warehouses.

Enabling faster deliveries

The electronics market is highly competitive, and BA acknowledges that their part in the value chain relies on serving their customers instantly.

«We’ve grown a lot in recent years and eventually ran out of space in our old warehouse. We weren’t rigged to expand at that warehouse and did not fulfill our potential in terms of efficiency» says Rolf Inge Danielsen, Logistics Director for Berggaard Amundsen.

BA needs their 25 service centers across Norway to have packages ready to ship the morning after they are ordered. Local electricians can also stop by the warehouse and pick up parcels just half an hour after they’ve placed an order.

«This has the potential to be the perfect warehouse for BA. It’s designed to fit their needs and support maximum efficiency, by for instance having the grid in close proximity to the goods receipt and the conveyor system from ITO in the ceiling. This allows trucks to take the shortest route. The entire warehouse is also designed for growth whenever BA is ready to scale up» says Poulsen.

Not just another distributor

The Logistics director from Berggaard Amundsen describes Element Logic’s work as essential for making the new warehouse a success.

«Element Logic is the best at understanding the customer and have helped us design a warehouse that fits our needs the best. They have guided us when we needed guidance – and pushed us when we needed to be pushed» says Danielsen.

«It felt safe having them there for every phase of the project. They attended all construction meetings, all workshops with employees, and also assisted us during the moving period. And they contributed with smart solutions every step of the way» Danielsen adds, who also highlights Element Logic’s vast experience as significant.

«Element Logic has been our partner in planning, moving, and establishing this warehouse. They are far more than just a supplier of robots» adds Bethina Samnøy Siristuen, Project Manager for Logistics at Berggaard Amundsen.

Utilizing AutoStore to its full potential

Although the warehouse is now up and running, Element Logic is still working closely with Berggaard Amundsen to achieve even better results.

«We had AutoStore in our previous warehouse too, but we did not utilize its full potential. Now, with Element Logic, we are investing time in learning how to use the software efficiently, having our employees take courses from Element Logic, as well as using live statistics to improve our workflow» Samnøy Siristuen explains.

Niklas Top Aanensen, Key Account Manager for Element Logic, is responsible for providing full support to Berggaard Amundsen during day-to-day operations. He says the aftermarket work they do is all about maximizing the potential of the client’s warehouse:

«The relationship we have with our customers is ongoing. We tweak and tune as much as we can and run simulations to see where they can improve. We look at order intake, how many ports they should have open at which working hours and when its most beneficial to re-stock bins, in addition to running software updates. We’re chasing efficiency, really» Top Aanensen concludes.

Facts and figures

- 12.200 m2 warehouse (14.000 m2 building including office space)

- 208 total employees (35 in the warehouse)

- 17 AutoStore robots

- 17,000 storage bins

- 2500 items picked daily from AutoStore

- 4 outbound carousel ports